Specialty Products

Trickling Filters Australia (TFA) is a wholly owned subsidiary of the Water & Carbon group, specialising in the supply of wastewater treatment and environmental restoration products.TFA have the knowledge and capabilities to assist with product supply and installation for a wide range of applications and uses.

To view the entire product range, please visit the TFA website.

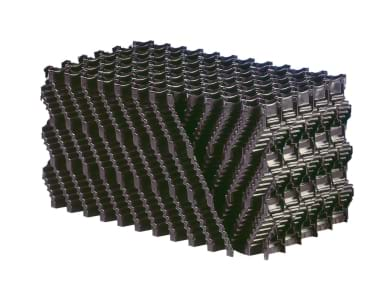

Trickling Filters

Innovations in plastic media has allowed trickling filters to drastically increase their level of effectiveness for a given treatment volume. Boasting 95% reductions in BOD and ammonia, plastic media trickling filters are a highly viable secondary treatment solution.

A key advantage of trickling filters, compared to other treatment technologies, is their very low power requirements.

Media can be supplied as complete modules or flat packed for on-site assembly. Our welding technology is environmentally friendly and does not use any solvents containing adhesives.

A key advantage of trickling filters, compared to other treatment technologies, is their very low power requirements.

Media can be supplied as complete modules or flat packed for on-site assembly. Our welding technology is environmentally friendly and does not use any solvents containing adhesives.

Random Packing Media

Random packing media is designed for application in both aerated and anoxic moving bed biofilm reactors. They aim to expand biofilm surface areas to specified levels, allowing for high quality treatment and reductions in sludge production and energy usage.

Random packing media provides an inexpensive way to upgrade your current system as it can use your existing infrastructure commonly without the need for additional capital works.

Media is supplied premade in various configurations with differing sizes and surface area measurements.

Random packing media provides an inexpensive way to upgrade your current system as it can use your existing infrastructure commonly without the need for additional capital works.

Media is supplied premade in various configurations with differing sizes and surface area measurements.

Lamella Clarifiers and Sedimentation Tanks

Lamella clarifiers are a highly efficient technology used in the removal of solids for both water and sewage treatment. They can increase the sedimentation capacity on a much smaller footprint than traditional systems, making it ideal for land-constrained sites.

TFA also supply a full range of sedimentation tanks for temporary or fast deployment requirements. Sedimentation tanks are fully equipped and are easily integrated into existing systems to ensure operations can commence quickly. Through their innovative design, they can also help to reduce costs and facilitate strong sludge concentration, while being easily adaptable to specific project requirements.

TFA also supply a full range of sedimentation tanks for temporary or fast deployment requirements. Sedimentation tanks are fully equipped and are easily integrated into existing systems to ensure operations can commence quickly. Through their innovative design, they can also help to reduce costs and facilitate strong sludge concentration, while being easily adaptable to specific project requirements.

Rotating Distributors (Distribution Arms)

Rotating Distributors are responsible for the equal and specified distribution of effluent over tricking filters. Modern distributors are specifically designed to reduce energy usage and maintenance cost, boasting expected lifespans of over 20 years.

VA Teknik Rotating Distributors can be installed in both new and existing wastewater treatment tanks and can be tailored to meet specific project requirements.

Maximising the usable surface area of the trickling filter through upgrading the rotating distributor can translate into considerable cost savings and better treatment outcomes.

VA Teknik Rotating Distributors can be installed in both new and existing wastewater treatment tanks and can be tailored to meet specific project requirements.

Maximising the usable surface area of the trickling filter through upgrading the rotating distributor can translate into considerable cost savings and better treatment outcomes.

BESE biodegradable product

Using a biodegradable starch-based product, BESE-elements® media create temporary structures for organisms to grow until they are strong enough to grow independently. It is typically used for organic structures, bank stabilisation, mussel and oyster bed creation, seaweed, and coral reed growth.

These stackable 3D matrix are made of potato waste and derived starch biopolymer. Single sheet elements click together to form a porous membrane structure that provides an establishment structure for ecosystem restoration.